Industry Application

Product Type

The Heart of Electric Vehicles – Traction Batteries

What is A Traction Battery?A traction battery is an electrochemical energy storage device, also known as a traction battery or deep cycle battery, it is a battery assembly that constitutes the energy storage used to power a vehicle’s traction motor and is used primarily as an energy supplier for electric vehicles (e.g., electric forklifts, industrial trucks, electric golf carts, electric pickup trucks, sweepers, cleaning vehicles, etc.) and as a consumer battery in superstructures such as mobile homes and ambulances (e.g. lighting, cooling, heating, various motors).

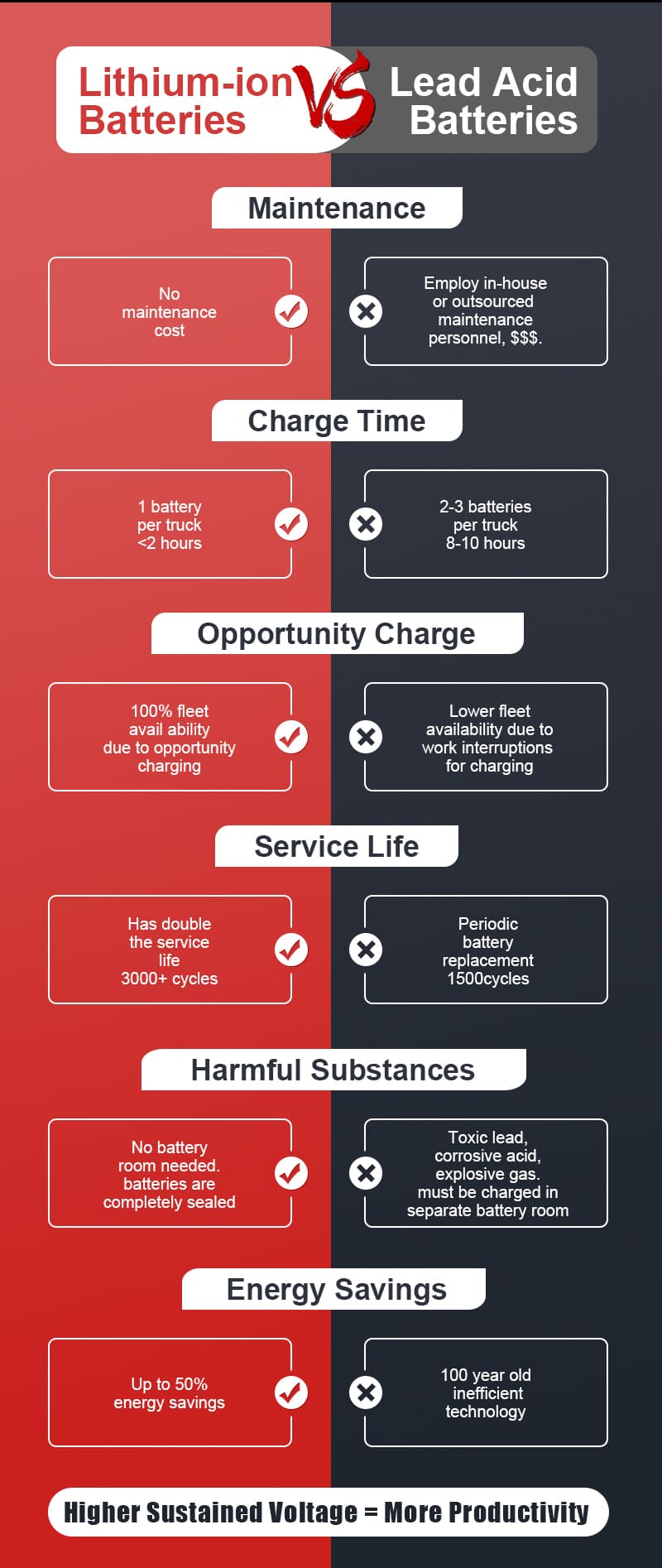

The traction battery or traction unit provides propulsion for the electric vehicle by converting the chemical energy stored in the battery into electrical energy. Typically, these traction cells are housed in a battery container. This is a steel container (or in the case of very small batteries, a plastic container) that corresponds to the forklift or other internal transport used for the traction battery. Towards An “Efficient, Sustainable and Low Carbon” Energy Transition.There is no turning back; the decarbonization of the economy has already begun. Increasingly, we are interacting with electric vehicles in our daily lives, at work or at leisure. These vehicles and tools powered by electric motors find the fuel tanks and fuel they need to move in traction batteries. The purpose of electric traction batteries is to store energy that can be used by electric motors, be it electric forklifts, industrial trucks, conveyors, palletizers, cleaning machines, golf carts, wheelchairs, etc. Due to the nature of their use, traction batteries must be engineered to meet two needs: power delivery and autonomy. Traction batteries must be able to withstand many charge-discharge cyclesTraction batteries are designed to withstand high cycling, i.e., large sequences of deep discharges and charges. Thus, during operation, they go through a discharge cycle, followed by a charge cycle and the necessary rest cycle before they can be used again. The optimal duty cycle for traction batteries is 8 hours of use, 8 hours of charge and 8 hours of rest. Therefore, in those cases where there is more than one operating shift, two or three batteries per vehicle should be considered, so that we respect the optimal duty cycle of each battery and its care, ensuring the productivity and maximum life of each battery. The voltage, power, and capacity of the traction battery depend on the system usedTraction batteries come in a variety of shapes and sizes and consist of a series of traction cells connected in series to form a 12, 24, 36, 40, 48, 72, 80 or 96 Volt battery. The power is determined by the “thickness” and height of each cell. At low power requirements, we can use a single cell type; however, as power and autonomy requirements increase, we must use a single interconnected 2V cell whose size varies according to amperage. Types of Traction BatteriesMonoblock-type power traction batteries can be found in their lead-acid, AGM or lithium battery variants. A single 2V cell for traction batteries (OPzS, OPzB) can be either a lead-acid or a GEL cell, in both cases consisting of flat or tubular plates. Realizing that there is no such thing as the “best battery” but rather the “best battery” for a specific need, maximizing performance and making our investment more efficient. It has to be admitted that lead-acid traction batteries are still the most popular because of the excellent price/performance ratio they offer. Their cost is the lowest on the market and they are safe, robust, and easy to maintain; but these batteries also have an Achilles heel: they require regular maintenance and given their high self-discharge rate and electrolyte consumption, and the fact that the acidic electrolyte tends to be harmful to the environment and humans, this is clearly not in line with our economic philosophy of green sustainability. In contrast, AGM, gel, and Li-ion battery technologies are more expensive, but they have minimal self-discharge and are complete “maintenance free”. They are hermetically sealed, so they do not leak or corrode surrounding components. In addition, they are equipped with gas conditioning valves (VRLA) making them ideal for installation in equipment operating in areas with little or no ventilation. The Achilles heel of these technologies is that they are highly susceptible to user abuse (compared to lead-acid technology) and in some cases require chargers with special features that are also more expensive.

Lithium Traction Battery ApplicationsThe declining status of conventional energy sources and changing environmental regulations have made lithium traction batteries, with their decreasing cost, the best choice for electric tractors, balancing: performance, productivity and cost. Well prepared to meet such needs, lithium traction batteries are recognized as the best and most reliable energy storage solution and are suitable for Auto lifts Electric trucks Mining tools Aircraft support equipment. Electric forklifts Railroads Obstacle-Fraggers Golf Carts Electric Motorcycle Aerial platforms Electric cleaning car Sweeper Electric excavator Marine

At BSLBATT Lithium, we design and manufacture all types and all applications of lithium traction batteries, providing you with a specific solution for every need. Our technical department is responsible for the delivery, start-up, and maintenance of lithium traction batteries. In addition, our business support services are dedicated to servicing the fleet in “your own plant”, thus avoiding productivity-damaging downtime and guaranteeing the maximum service life of your equipment. |

A Guide to Choosing the Best 48V Lithium Golf Cart Battery

Would it be worth investing in a 48V ...

10 Exciting Ways To Use Your 12V Lithium Batteries

Back in 2016 when BSLBATT first began designing what would become the first drop-in replacemen...

BSLBATT Battery Company Receives Bulk Orders from North American Customers

BSLBATT®, a China Forklift battery manufacturer specializing in the material handling indust...

Fun Find Friday: BSLBATT Battery is coming to another great LogiMAT 2022

MEET US! VETTER’S EXHIBITION YEAR 2022! LogiMAT in Stuttgart: SMART – SUSTAINABLE – SAF...

Looking for new Distributors and Dealers for BSL Lithium Batteries

BSLBATT battery is a fast-paced, high-growth (200% YoY ) hi-tech company that is leading the a...

BSLBATT to Participate at MODEX 2022 on March 28-31 in Atlanta, GA

BSLBATT is one of the largest developers, manufacturers, and integrators of lithium-ion batter...

What makes the BSLBATT the Superior Lithium Battery for your Motive Power needs?

Electric forklift and Floor Cleaning Machines owners who seek the ultimate performance will fi...